5 things that affect your concrete delivery cost

Planning for a concrete pour involves more than just ordering the right quantity. Your concrete delivery cost can shift depending on factors like timing, location, and site access. Whether you're working on a large-scale project or a simple slab, understanding these variables helps avoid delays and unexpected charges. Here's what to consider before booking your ready-mix concrete delivery.

1. Delivery distance and location

One of the biggest factors in your concrete delivery cost is how far your site is from the supplier’s batch plant. Longer distances mean more time on the road, higher fuel usage, and tighter scheduling requirements — all of which contribute to the overall price. If you’re based in an outer suburb or an area with limited local supply options, it’s worth checking availability in advance so you can organise a delivery window that fits your timeline and budget.

2. Order volume and minimum load fees

Concrete is typically charged by the cubic metre, but suppliers also work to minimum truckload volumes. If your order falls below that threshold, you’ll likely be hit with a minimum load fee to fill the gap. To avoid paying for unused capacity, it’s best to calculate your required quantity carefully — or, if possible, batch smaller jobs together into a single pour. That way, you’ll make better use of the ready-mix concrete you’re paying for and reduce waste at the same time.

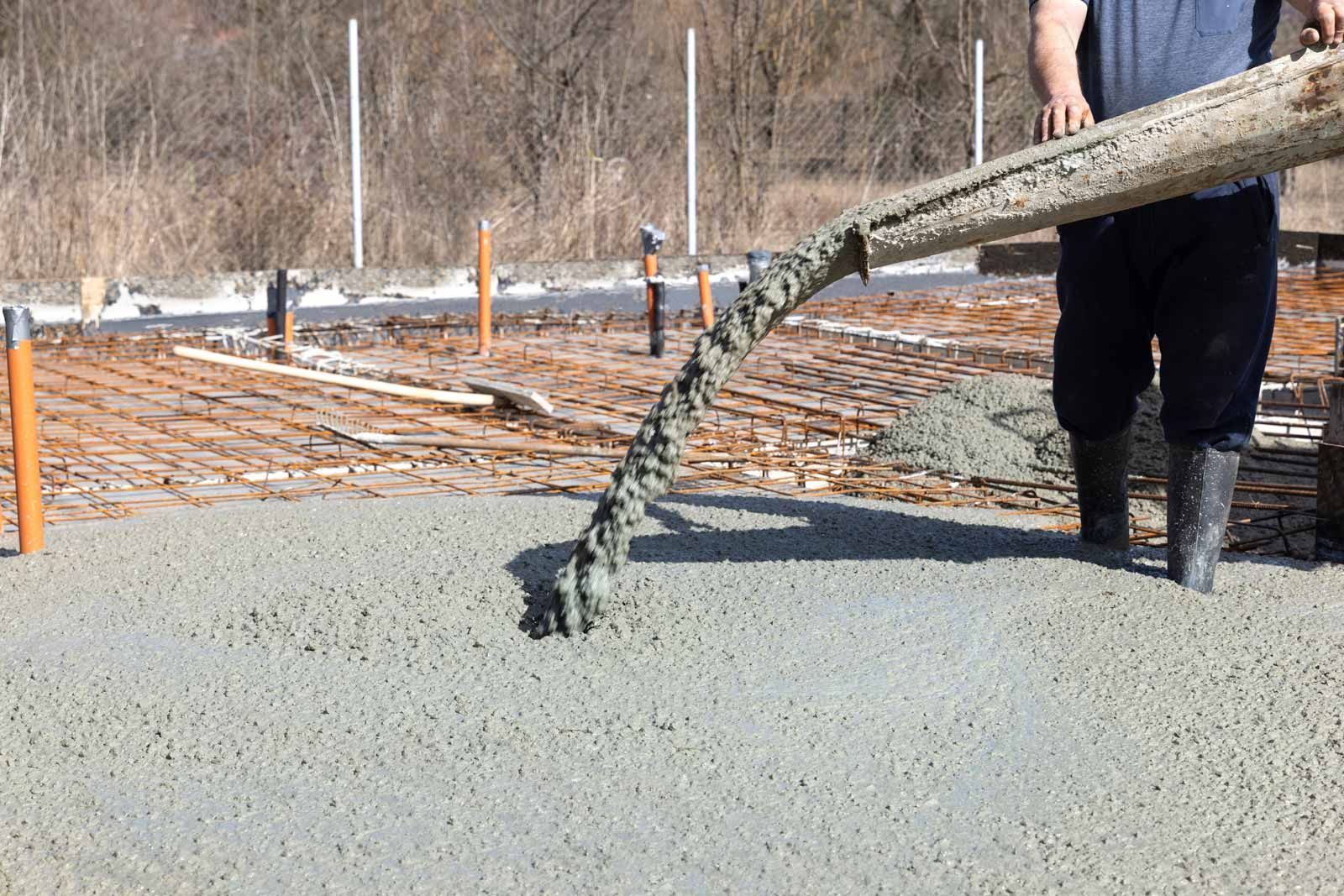

3. Site access and pumping requirements

Every site is different, and access can play a major role in how your concrete delivery is handled. If a truck can’t get close enough to the pour area, you may need to bring in a line pump or boom pump to reach the right spot. These setups come with additional equipment and labour considerations, which can increase your overall concrete delivery cost. The more complex the access or the longer the pumping distance required, the more planning (and budget) you'll need to allocate to keep the job running efficiently.

4. Waiting time or delays on site

Most suppliers allow a certain amount of waiting time as part of their delivery service, but if the truck is left idle for too long, extra fees start to add up. Delays can happen when the site isn’t fully prepped, the crew isn’t ready to pour, or if there are hold-ups with equipment setup. To avoid being charged for unnecessary downtime, it’s important to ensure the pour area is ready, the pump is positioned, and your team is set to go before the truck rolls in. Good coordination can save both time and money.

5. After-hours or weekend delivery

Concrete deliveries that fall outside standard business hours often attract premium rates. Early mornings, evenings, weekends, or public holidays typically require additional scheduling effort from both the supplier and the pump crew, which is reflected in the price. If your project schedule demands a non-standard delivery window, it’s a good idea to confirm availability and any surcharges early in the planning process. Wherever possible, sticking to normal hours will help keep your overall delivery cost down.

Keep your costs low with the right planning from Get Pumped

Understanding what influences your concrete delivery cost is the first step to keeping your project on track and within budget. At Get Pumped, we work closely with builders, homeowners, and developers to coordinate efficient, no-fuss delivery across Melbourne. From matching your ready-mix concrete needs with the right truck and volume, to working with the batch plant and pumping crew to ensure everything runs smoothly on site, we’re here to help. If you require straightforward advice and a team you can trust, contact us today to arrange your next delivery.